Introduction.

Introduction.

Electrolytic capacitors go wrong. An engineer I used to work with once said that as long

as there were electrolytic capacitors there would be jobs for engineers. He was right.

An ESR meter is a meter that can be used to test the ESR of electrolytic capacitors,

along with other components and can become an invaluable tool in the engineers toolbox.

What is ESR?

No capacitor is perfect, as well as its capacitance it will also have some inductance and

some resistance and it is equivalent series resistance, which is like having a resistor

in series with an otherwise perfect capacitor, that can come to dominate in a failing

capacitor. As this resistance increases ripple current, which in switch mode power

supplies can be many amps, causes the capacitor to heat up due to resistive loses and

this heating accelerates the demise of the capacitor by drying out the electrolyte at a

faster rate.

A good capacitor of 1uF or more may have an ESR of less than one ohm but as it ages this

value will increase to many ohms and even many tens of ohms. The life for an electrolytic

capacitor depends on the quality of construction, its ripple current and the temperature

that it is operated at and can be as little as a few thousand hours in some cases.

|

The circuit.

The circuit.

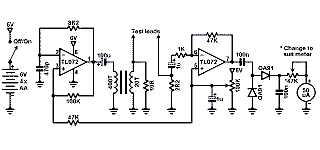

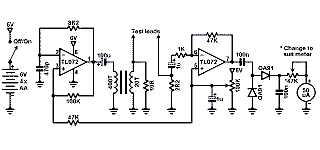

The circuit is really quite simple. One half of the TL072 is configured as a relaxation

oscillator oscillating at about 100KHz. The output from this has its DC component

removed by a 100uF electrolytic capacitor before being fed to the primary of a small

step down transformer. This transformer performs two functions, it reduces the signal

amplitude from over 4V peak to peak to about 200mV peak to peak and reduces the

impedance from around 300 ohms to less than one ohm. The 10 ohm resistor across the

output of this transformer acts as a minimum load to reduce output level variations.

One consequence of having such a low voltage low impedance signal source is that the

capacitors can usually be tested without removing them from circuit.

This test signal is applied to the capacitor under test and returns via a 2.2 ohm

resistor with which it forms a voltage divider. The voltage across this resistor is

amplified by the other half of the TL072 before being rectified and smothed and then

applied, via an adjustable resistor, to the 50uA meter. As this voltage is inversely

proportional to the series resistance of the capacitor the lower this resistance the

greater the defelection of the meter.

|

Construction.

Construction.

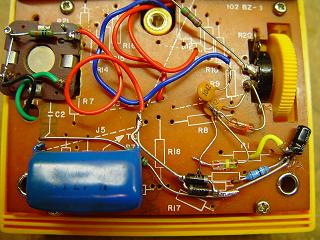

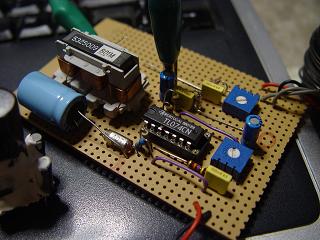

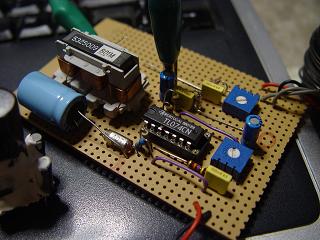

Construction is not critical and, as some components like the transformer core were

selected from what was available at the time, a printed circuit board is not really

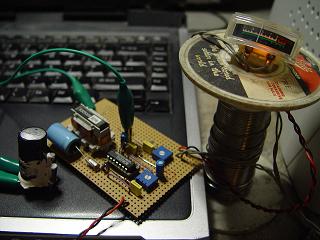

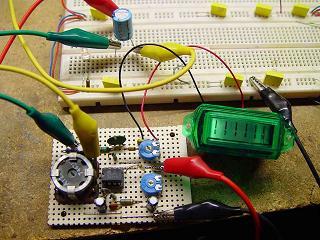

practical. The first two prototypes were built entirely on stripboard, the last one

partly on stripboard and partly on the remains of the donor multimeter circuit board.

The 100K pot in the circuit is any subminature type but the adjustable meter series

resistor should be easy to adjust by hand as its setting will need to be varied to set

the meter zero which will depend on the leads used with the meter and the age of the

batteries. In the old multimeter used for the last version there was such a pot already

present and this, along with a fixed resistor, was used as the meter series resistor.

|

The transformer can be wound on any small ferrite core that has room for all the 400

primary turns and the 20 secondary turns. The actual core used is not critical, almost

any ferrite core will do, and the small feedback tranformers in computer power supplies

or the output transformer from a cold cathode fluorescent lamp inverter would be ideal.

The first prototype and this version used the core from an audio filter inductor while

the second prototype, seen here, used a transformer that already had two ten turn

windings that were used in series and a winding with many hundreds of turns that was

unwound until only about four hundred turns remained.

No special care needs to be taken winding the transformer, I wound the secodary first

and then wound the primary directly over it using 30 SWG, 28 AWG, coated copper wire

for both the primary and secondary.

How yet another transformer was made is detailed on its

own page.

|

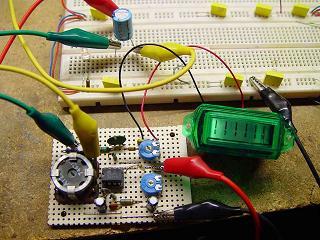

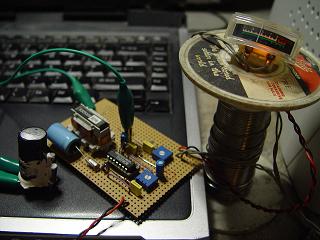

The meter is also not critical, Any meter that is sensetive enough, i.e. 150uA or better,

can be used. The first prototype used a tuning meter from an old FM receiver, the second,

shown here, used the signal strength meter from a CB radio.

The series resistor to the meter should be chosen to suit the meter, the better the

sensetivity the higher value it should be. In the first prototype this resistor was only

10K ohms but for the 50uA multimeter meter the original 39K ohms adjustable resistor was

reused along with a 27K fixed resistor to give a usable range.

If a resistor of much more than 47K or so is needed for the meter the gain of the

detector stage can be reduced instead by reducing the value of the 47K feedback

resistor between pins 6 and 7 of the TL072.

|

Setting up

Setting up

Before powering the first time the 100K preset pot should be set to about midway, the

meter series resistor should be set to maximum and the test leads should be connected

together. If all is well when the circuit is powered the meter should show some

deflection and this should be adjusted with the meter series resistor to give a reading

near full scale. Now the 100K preset pot should be adjusted to give the maximum reading,

this should not be far from the position it is already set at.

Now the meter should be closed up and, with the leads still connected together the meter

series resistor adjusted to full scale. That's it, the meter is now ready to use.

Calibration

Once the meter is set up and working you may wish to make a calibrated scale for it. The

easy way to do this is to use a series of good accuracy, say 1%, low ohm resistors and

testing each in turn mark its value on the meter scale. You can then photograph or scan

this scale and use it as a template to print out a new scale for your meter. In the case

of this meter the original ohms scale, although reading ten times the actual value, is

close enough to be used at is.

|

In use

In use

One feature of an ESR meter such as this is that in almost all cases it can be used to

check capacitors without removing them from circuit but not while the circuit is still

powered, especially mains filter capacitors. This is because of the low voltage

test signal and because a good capacitor will be almost a short circuit, so any other

components connected connected to the capacitor will have a minimal effect on the

measurement. The one case where this is certainly not true is when trying to measure

one of the many parallel capacitors such as supply decoupling capacitors on a logic

board.

|

The use of the ESR meter does not stop at testing capacitors though. It can also be used

to test for shorted junctions in semiconductors such as switching transistors in switch

mode power supplies and cold cathode fluorescent inverters or failed diodes in a bridge

rectifier or diode stack. Instances where a standard ohms meter and even a diode tester

can give uncertain results. It can also be used to some extent to test ferrite cored

inductors and transformers for shorted turns. In this case an open circuit is a good

thing as it shows that the inductance of the test subject is large enough to be a

significant impedance at the test frequency.

These features can make an ESR meter an essential tool for troubleshooting electronic

equipment.

|

400V input protection

400V input protection

Sooner or later I'm sure I'll try to measure the ESR of a capacitor that is charged or

even still powered. This modification should go some way to protecting the meter from

being damaged by this kind of mistake.

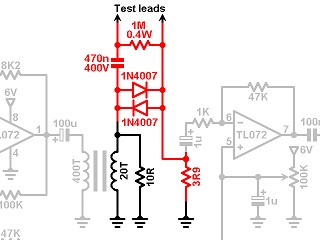

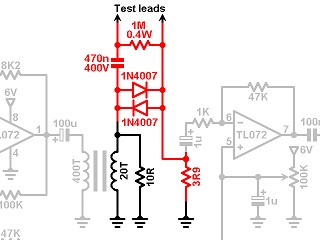

The added components, shown in red, are a 400V 470nF unpolarised capacitor to block any

DC voltage and two back to back 1N4007 diodes to divert any charging current for this

capacitor away from the transformer and associated components. Finally a 1M ohm 0.4W

resistor is added across the test leads to dissipate any charge on the 400V 470nF

capacitor.

In normal use the two back to back 1N4007 diodes never conduct so have no effect on any

measurements made and the 1M ohm resistor likewise is far too large to matter. The 400V

470nF capacitor does change the signal source impedance a little and to compensate for

this a 3.9 ohm input resistor, also shown in red, replaces the original 2.2 ohm resistor

to keep the scale calibrated.

|

Any of the 1N400x range of diodes could be used, I used 1N4007s because that's what was

to hand at the time. The maximum reverse voltage they ever see will only be the forward

voltage of the other diode, so there is no need for high reverse voltage parts.

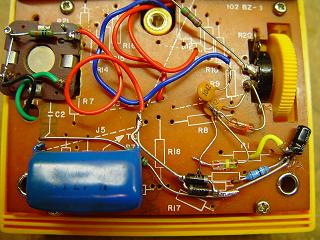

The added components were fitted onto the remains of the original multimeter circuit

board. The 1M ohm discharge resistor can just be seen underneath the 400V 470nF capacitor

and alongside those are the two back to back 1N4007 diodes. All the added components fit

easily within the donor multimeter case.

|

Introduction.

Introduction.

The circuit.

The circuit.

Construction.

Construction.

Setting up

Setting up

In use

In use

400V input protection

400V input protection