|

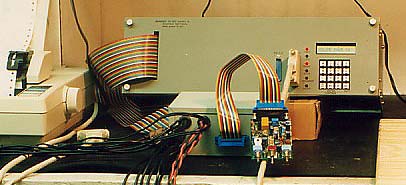

6502-based ATE Pages: Project Description  This is a 6502-controlled automated test equipment (ATE) setup I made and

programmed at my last place of work in about 1990. It is shown testing one

of the products on a board of about 2.25" x 4.5" near the front edge of the

workbench. This setup is much more compact than previous ones I had done

which used some high-doallar Hewlett-Packard and other IEEE-488 equipment

stacked in a 19" rack. This new setup had signal generators, DMM, loads,

amplifiers, power supplies, switching matrices, etc.. in a 3U 19" rack

cabinet. It's all controlled by a Cubit 6502 SBC running Forth. The

program was about 10,000 lines of compact code. It would do scores of tests

on dozens of different models of the products, yet the program and all test

parameters compiled to about 38KB with Forth headers (or about 28KB

without). This project is what really got me going in Forth on the 6502.

Using Forth, I was able to spend my time figuring out hardware problems

instead of debugging software. (Forth does make hardware problems easier to

figure out.) After I released the ATE to the production floor for everyday

use, no one ever found any bugs in it. I know they used it for at least 8

years after I made it, and they may still be using it today. They paid me

to service it a few times after I left the company, for things like an IC or

relay that went south, or a cable that became undependable from being flexed

tens of thousands of times.

This is a 6502-controlled automated test equipment (ATE) setup I made and

programmed at my last place of work in about 1990. It is shown testing one

of the products on a board of about 2.25" x 4.5" near the front edge of the

workbench. This setup is much more compact than previous ones I had done

which used some high-doallar Hewlett-Packard and other IEEE-488 equipment

stacked in a 19" rack. This new setup had signal generators, DMM, loads,

amplifiers, power supplies, switching matrices, etc.. in a 3U 19" rack

cabinet. It's all controlled by a Cubit 6502 SBC running Forth. The

program was about 10,000 lines of compact code. It would do scores of tests

on dozens of different models of the products, yet the program and all test

parameters compiled to about 38KB with Forth headers (or about 28KB

without). This project is what really got me going in Forth on the 6502.

Using Forth, I was able to spend my time figuring out hardware problems

instead of debugging software. (Forth does make hardware problems easier to

figure out.) After I released the ATE to the production floor for everyday

use, no one ever found any bugs in it. I know they used it for at least 8

years after I made it, and they may still be using it today. They paid me

to service it a few times after I left the company, for things like an IC or

relay that went south, or a cable that became undependable from being flexed

tens of thousands of times.

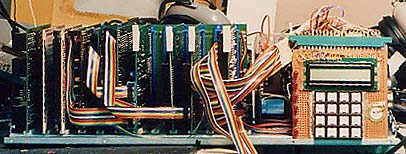

Same ATE, with the case open, during development. I made two sets. The

original plan was for up to seven, but that became unnecessary. This used

STD bus (which, BTW, stands for "simple to design," not "standard.") The

boards are about 4.5 x 6.5", with 56 contacts at the edge connector.

Same ATE, with the case open, during development. I made two sets. The

original plan was for up to seven, but that became unnecessary. This used

STD bus (which, BTW, stands for "simple to design," not "standard.") The

boards are about 4.5 x 6.5", with 56 contacts at the edge connector.

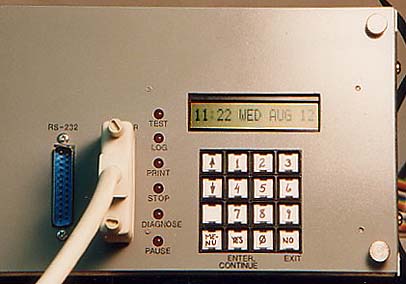

A close-up of the operator interface. With the earlier setup using the

HP-9000-series computer, the test operator had a large screen and keyboard,

which proved troublesome. The idea here was to only give the operator

access to what (s)he needed to do. As it turned out, it would have been

nice to have the LCD a little bigger than 16-character, 1-line-- maybe a

40x2. It fit the bill pretty well though. Failing test results always got

printed out so the paper would get rubber-banded to the unit to go back to

repair. Optionally, all test results could be printed, or archived for

later download to a PC to analyze with something like Lotus 1-2-3.

A close-up of the operator interface. With the earlier setup using the

HP-9000-series computer, the test operator had a large screen and keyboard,

which proved troublesome. The idea here was to only give the operator

access to what (s)he needed to do. As it turned out, it would have been

nice to have the LCD a little bigger than 16-character, 1-line-- maybe a

40x2. It fit the bill pretty well though. Failing test results always got

printed out so the paper would get rubber-banded to the unit to go back to

repair. Optionally, all test results could be printed, or archived for

later download to a PC to analyze with something like Lotus 1-2-3.

|